NDT

HomeNDT

Pride Consulting Enginners

Non Destructive Test Method

NDT Method

Ultra Pulse Velocity Tests

IS Codes applicable: As per IS 13311. (Part 1): 1992

Applications of the test:

The test is performed on structural elements. Homogeneity of Concrete. Presence of Cracks, Voids & Other Imperfections. Changes in Concrete Structure with time. Velocity co-related to strength.Equipment Used:

Electric Pulse Generator. Transducer: One Pair. Amplifier. Electronic Timing Device.Test basis:

Ultrasonic pulses travel faster in denser material. Each material has typical ultrasonic pulse velocities. E.g. steel, Concrete etc. using benchmarks over a period of time and conducting extensive laboratory and in-situ tests, we have co-related ultrasonic pulse velocity and estimated strength.

Methodology:

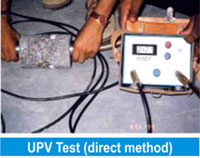

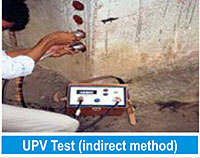

Assess access, Single sided, double sided etc on the structural element Clean the concrete surface thoroughly (on plaster or without plaster). Apply grease on the concrete surface where test is to be conducted. Press probes on the surface of the structural element to remove air gaps. Note down the distance between the 2 probes. Read time taken for the ultrasonic pulse from the instrument. Calculate Velocity = distance / time Repeat the test on multiple areas of the element if necessary. Test at different members of the structure.

Influencing factors for readings:

Readings taken on plaster or directly taken. New/old construction in elements. New + old material (e.g. jacketed columns where new and old concrete coexist). Single sided or double sided access. (indirect or direct) Grade of Concrete.

Understanding results:

The estimated strength may vary from actual strength up to about +/- 15%. or so. In order to confirm the findings of the tests, core tests may be conducted on a select sample of elements, if necessary. The interpretation of strength of concrete from the UPV is based on our experience, judgment & to the best of our knowledge.The IS code 13311 (Part 1) 1992 (Indian Standard Code of Practice) gives velocity.

Criterion for concrete quality grading, part of which is reproduced below:

| Sr. No | Pulse velocity be cross probing (direct method) | Concrete Quality Grading |

|---|---|---|

| 1 | Above 4.5 km/s | Excellent |

| 2 | 3.5 km/s to 4.5 km/s | Good |

| 3 | 3.0 km/s to 3.5 km/s | Medium |

| 4 | Below 3.0 km/s | Doubtful |

However the code does not give any interpretation of UPV in terms of strength. Hence the IS code grading should be taken only as guidelines. However our experience shows that for M20 grade concrete a velocity of 3.5 km/s may be good but for high strength concretes like M40 or M60, the velocities for both may be above 4.5 km/s, however M40 cannot be used in place of M60, hence the IS code grading should be taken only as guidelines. For new construction, for concrete grades higher than M30, the customer must provide reference cubes, crushing results and mix design in order to correctly arrive at the estimated strength.